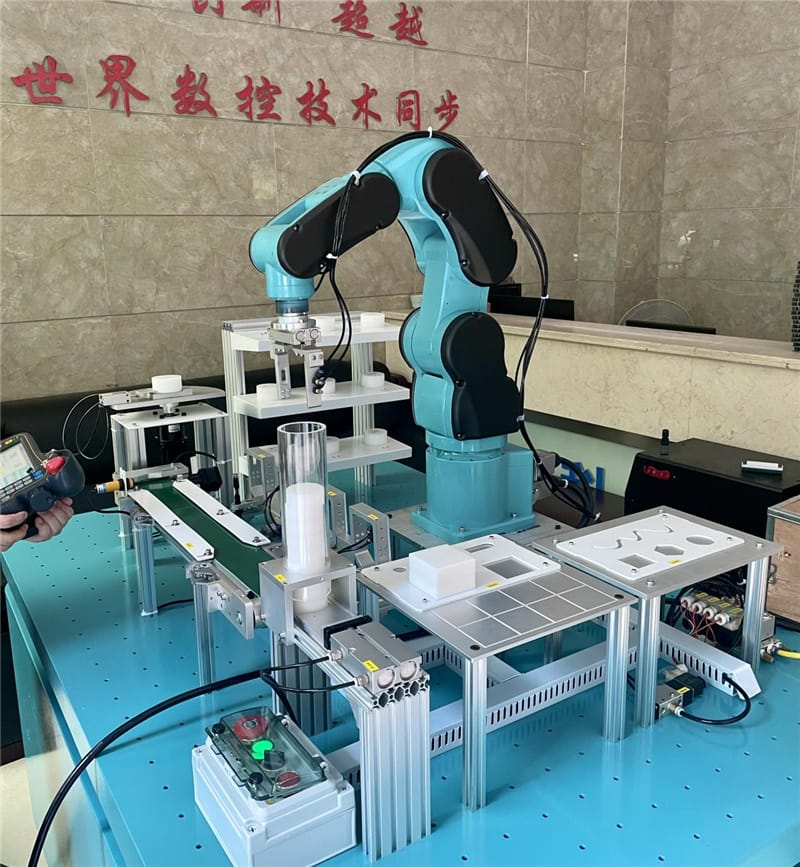

6 axis welding robot arm controller

Sehlahisoa Tšobotsi

1. Le ka mohla u se ke ua hatakela mochini, sistimi e nang le ts'ebetso ea sehopotso (Ts'ebetso ea Abosolute)

2. Ha ho hlokahale hore u kenye moeli o thata ho "4-8 joint axis welding robot controller kit" eohle le ho khutlela sebakeng sa zero (Tlhahiso ea Abosolute)

3. Sebelisa mohala o hokahantsoeng le taolo ka ts'ebetso ea Wifi, e bonolo ebile e bonolo ho romella lenaneo (Sebopeho sa NewKer)

4. Lenaneo la G code, ke molaoli oa liroboto oa NewKer-CNC feela ea ka sebetsang le lenaneo la G code joalo ka cnc controller (Sebopeho sa NewKer)

5. Ruta ts'ebetso e nang le paramethara ea technics, e bonolo ho e sebelisa (Sebopeho sa NewKer)

6. PLC le lenaneo la macro kaofela li butsoe (NewKer tšobotsi)

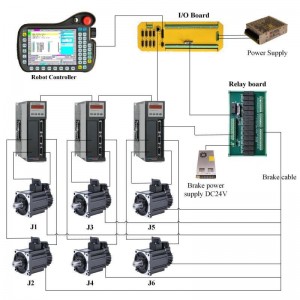

7. Ke thapo e le 'ngoe feela e tsoang ho molaoli, ho bonolo ho hokela (Tlhahiso ea mofuta oa bese)

8. Ts'ireletso ea li-password tse sa reroang tsa maemo a mangata, polokeho e eketsehileng (NewKer tšobotsi)

Lintlha tsa paramethara (G khoutu e bonts'a)

1.No. of controller shaft:4-8 axiscontrol panelof industrial automatic motoman arc welding robot(j1,j2,j3,j4,j5,j6)

2. Mofuta: Mofuta o felletseng oa bese le mofuta oa servo

3. Mananeo a mangata ka ho fetisisa:±99999.999

4. Encoder ea enjene:17bits le 23bits

5. Lintlha tsa I/O: 48*32 I/O

6. 0-10V analoge: 2 litsela 0-10V analoge

7. Ts'ebetso: Ruta, Lefa, Hole

8. Wifi tshebetso: Hokela le fono ho romela lenaneo

9. Mosebetsi oa RS 232: RS232 ho hokahanya le PC

10. Ts'ebetso ea USB: Ntlafatsa le ho romella lenaneo

11. Mokhoa oa lenaneo: Ruta, G khoutu, Technics parameter

12. Mosebetsi oa ho sisinyeha: Supa ho supa, mola o otlolohileng, arc

13. Litaelo:Movement,Logic,Calculation,Technics,G khoutu ho CNC

14. Sistimi e hokahanyang: Joint, User, Tool, World

15. Mosebetsi oa PLC: Fetola lere, mehato e 8000

16. Tlhahisoleseding ea alamo: Tšohanyetso, khanna, tlhokomelo, phoso ea ho qala arc le ho hokahanya

17. Moeli oa tšebetso:Moeli o bonolo

18. Algorithm ea molaoli:

1) Vertical multi joint serial tobot;

Roboto ea parallelogram e otlolohileng;

3) Roboto ea letsoho e emeng e kopantsoeng ea L e ngata;

4) Roboto e hokahanyang poleiti;

5) SCARA roboto;

6) roboto ea Delta;

7) roboto e khethehileng;

19.Tshireletso ea password: Tšireletso ea Multilevel e sa reroang

Lenaneo la 20.User macro:Na le

21.Mosebetsi oa lisebelisoa tsa motlakase: E-ba le

22. Kopo: welding, palletizing, penta, ho hlokomela, ho itšeha ka laser le letsoho le leng le khethehileng la robor.

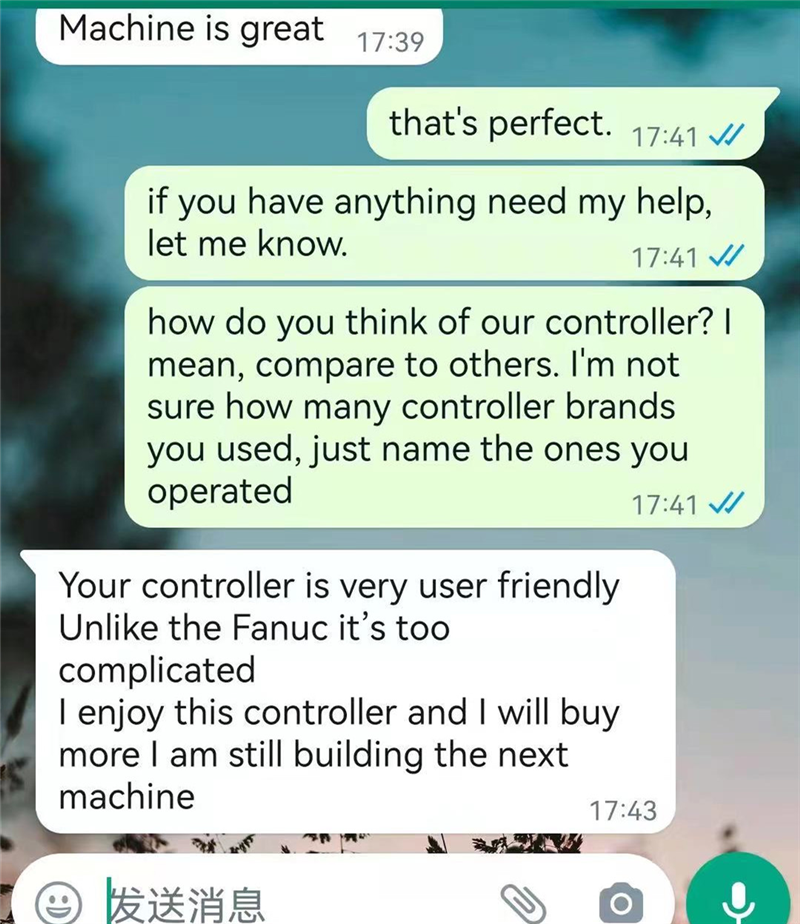

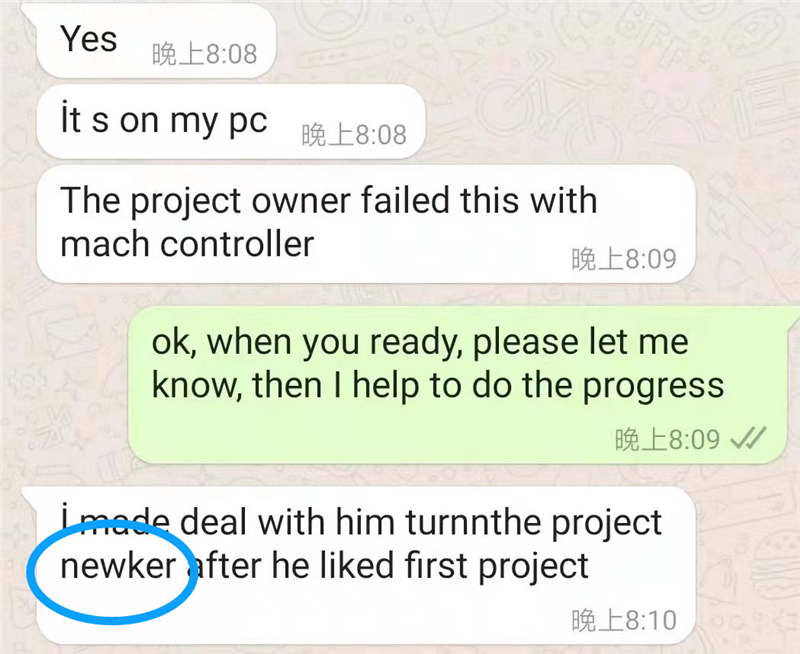

Thoriso ya Bareki

Customer Case