1-10 Axis Lathe Milling Turning Center Drilling Controller 1500MD

Lihlahisoa tsa lihlahisoa

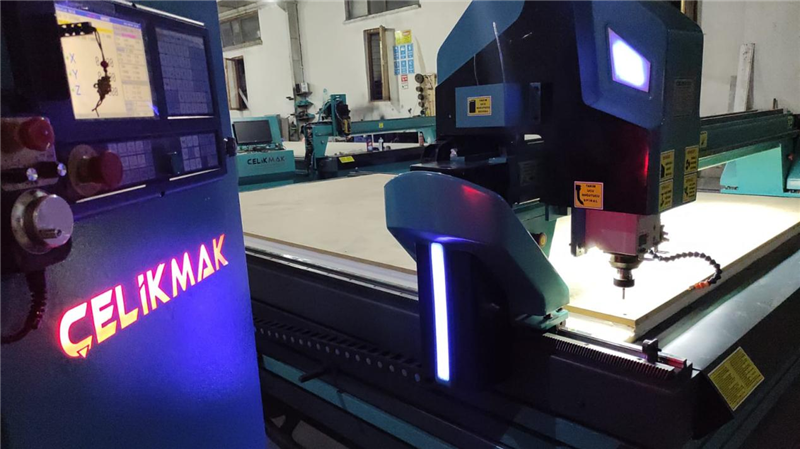

Kopo: Setsi sa Lathe le Turning, Mochini oa CNC oa Boring, mochini o sebetsang oa lehong oa CNC, mochini oa CNC Milling, mochini oa ho phunya oa CNC, mme haholo lisebelisoa tsa othomathiki.

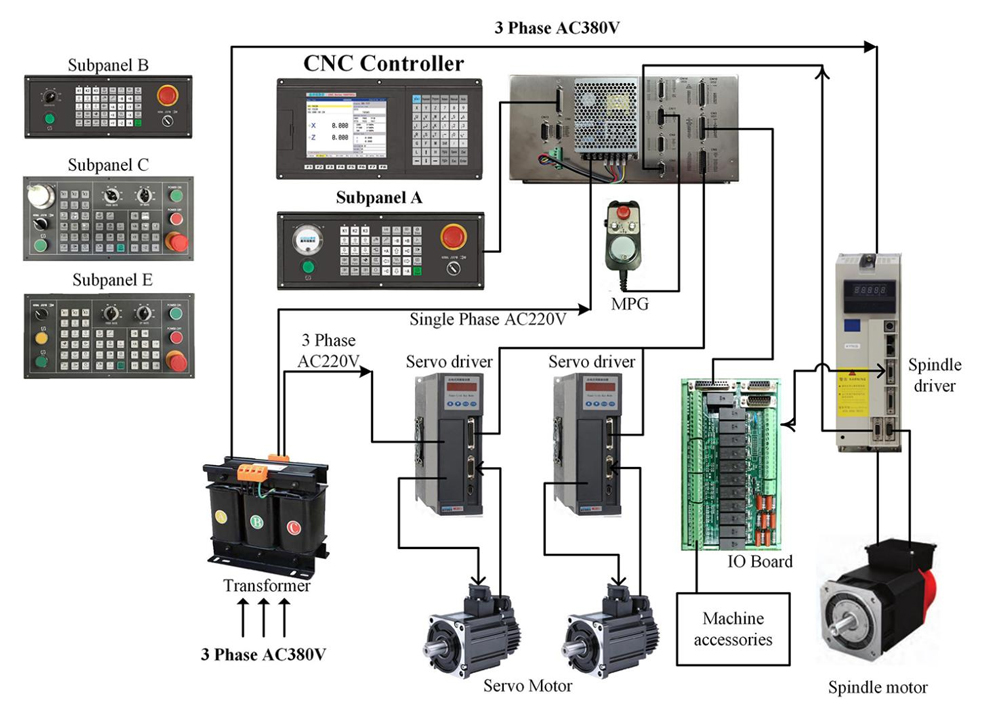

Axis: 1-10 axis

Tlaleho ea Teko ea Mechini: E fanoe.

Mosebetsi: Tšehetsa ATC, Macro function, le PLC displayer

Likarolo tsa mantlha: PLC, CNC, Macro program, CNC controller.

CPU: ARM(32bits)+DSP+FPGA.

Boema-kepe: 56input 32output

Boima ba 'mele: 8KG

Kamore ea polokelo ea mosebelisi: 128Mb

Sebopeho: USB+RS232 Communction Port.

Matla a Phepelo: 10000 Set / Sets ka Khoeli.

Warranty: Lilemo tse 2

Lintlha tsa paramethara (G khoutu e bonts'a)

1. Fumana ka potlako: G00

2. Kenyelletso ea mela e otlolohileng: G01

3. Tlhaloso ea Arc: G02/03

4. Potoloho ea ho itšeha cyliner kapa khoune: G90

5. Potoloho ea ho itšeha sefahleho: G94

6. potoloho ea ho seha khoele: G92

7. Potoloho e tsitsitseng ea ho tlanya: G93

8. Potoloho ea sehiloeng ka mahoashe ka excircle: G71

9. Potoloho ea ho khaola ka thata qetellong ea sefahleho: G72

10. Potoloho ea ho khaola ho koetsoeng: G73

11. Potoloho ea ho phunya lesoba le tebileng qetellong ea sefahleho: G74

12. Potoloho ea ho itšeha groove ka bophara ba ka ntle: G75

13. Potoloho ea ho khaola khoele ea motsoako: G76

14. Potoloho ea lenaneo: G22,G800

15. Sistimi ea khokahano ea lehae: G52

16. Lemoha taelo ea ho tlola: G31,G311

17. Pole coordinate: G15, G16

18. Lenaneo la Metrical/Imperial: G20,G21

19. Seta ho hokahanya, ho fokotsa: G184,G185

20. Mokhoa oa ho hokahanya oa workpiece: G54~G59

21. Tool radius C: G40, G41, G42

22. Mokhoa o nepahetseng oa ho fumana sebaka / mokhoa o tsoelang pele: G60 / G64

23. Mokhoa oa ho fepa: G98,G99

24. Ho tšehetsa ntlha ea ho qala lenaneo: G26

25. Ho tšehetsa ntlha e tsitsitseng: G25, G61, G60

26. Ho tšehetsa ntlha ea datum: G28

27. Emisa: G04

28. Lenaneo la Macro: G65, G66, G67

29. Mosebetsi o thusang: S, M, T

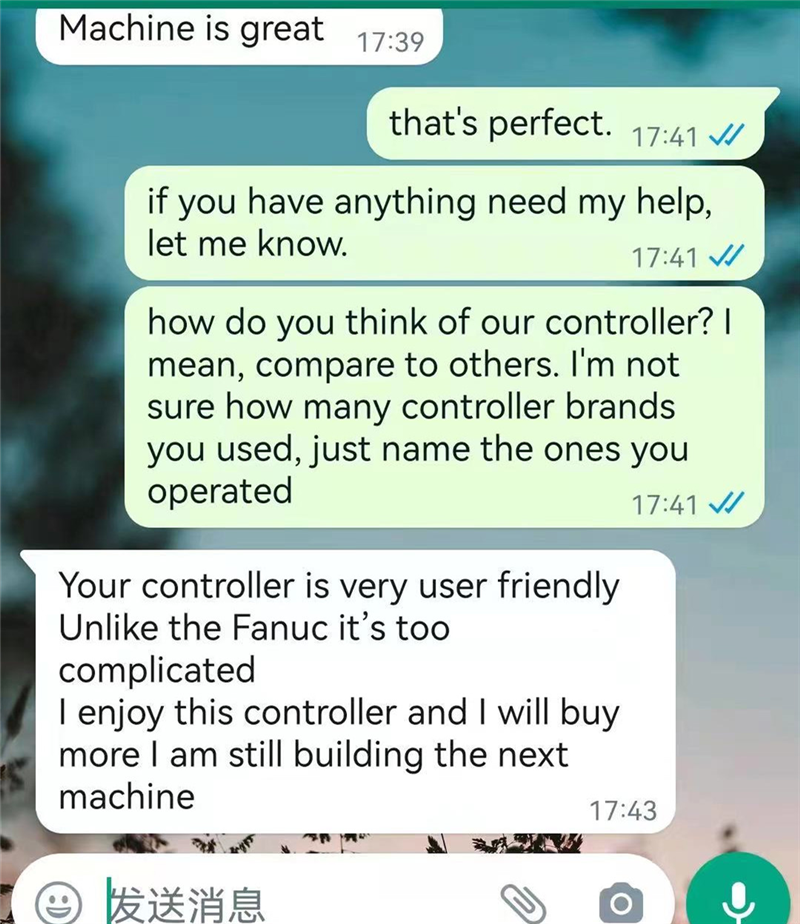

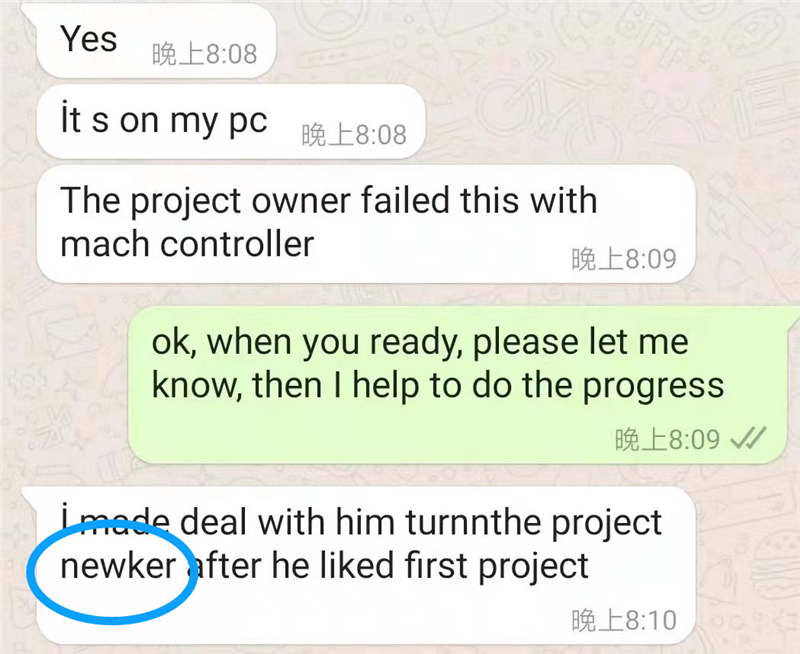

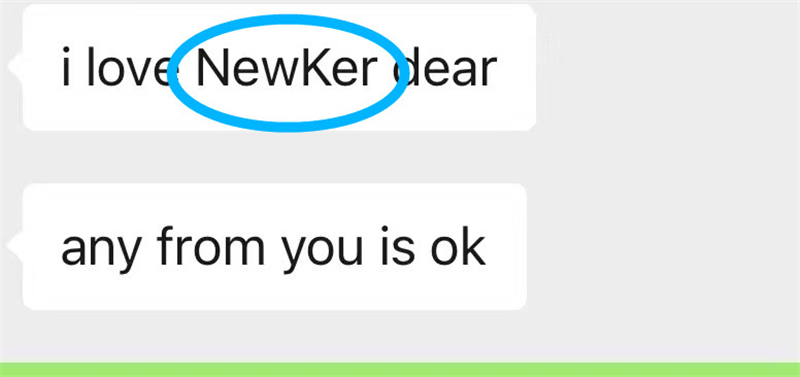

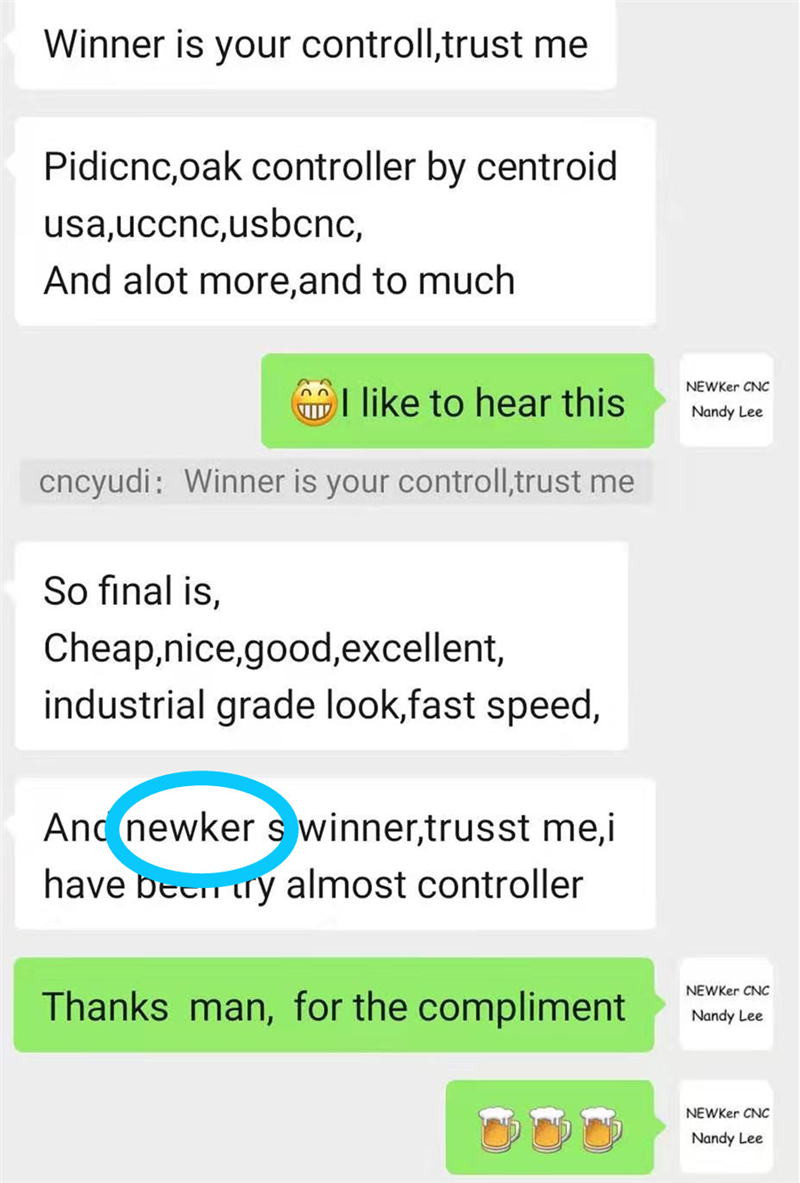

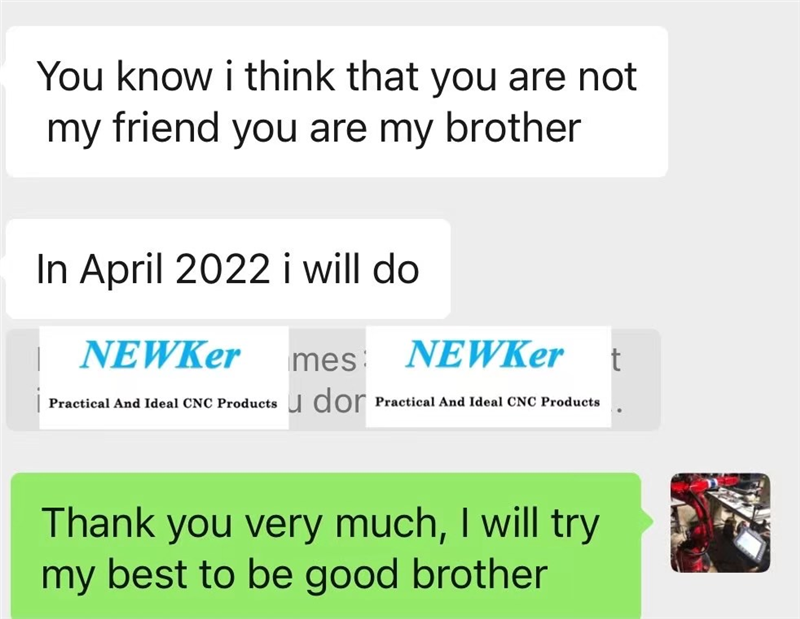

Thoriso ya Bareki

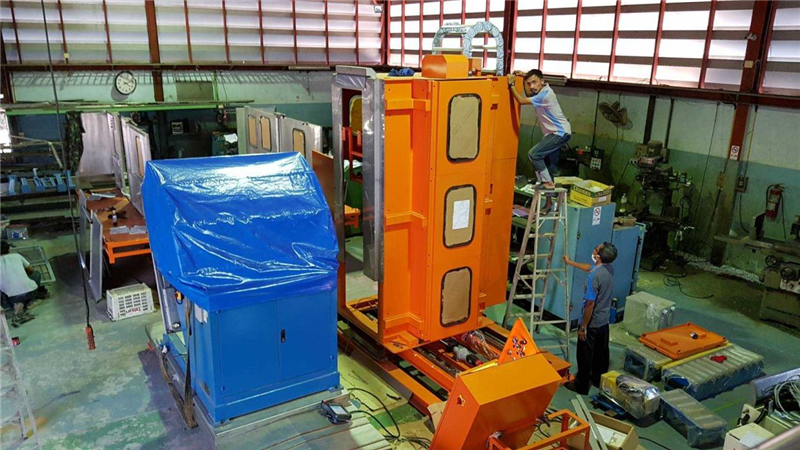

Customer Case