1000 Series 2 3 4 5 Axis Machining Center Controller e nang le ts'ebetso ea RTCP

Likarolo tsa Sehlahisoa

1.Adopt standard g khoutu ea machaba

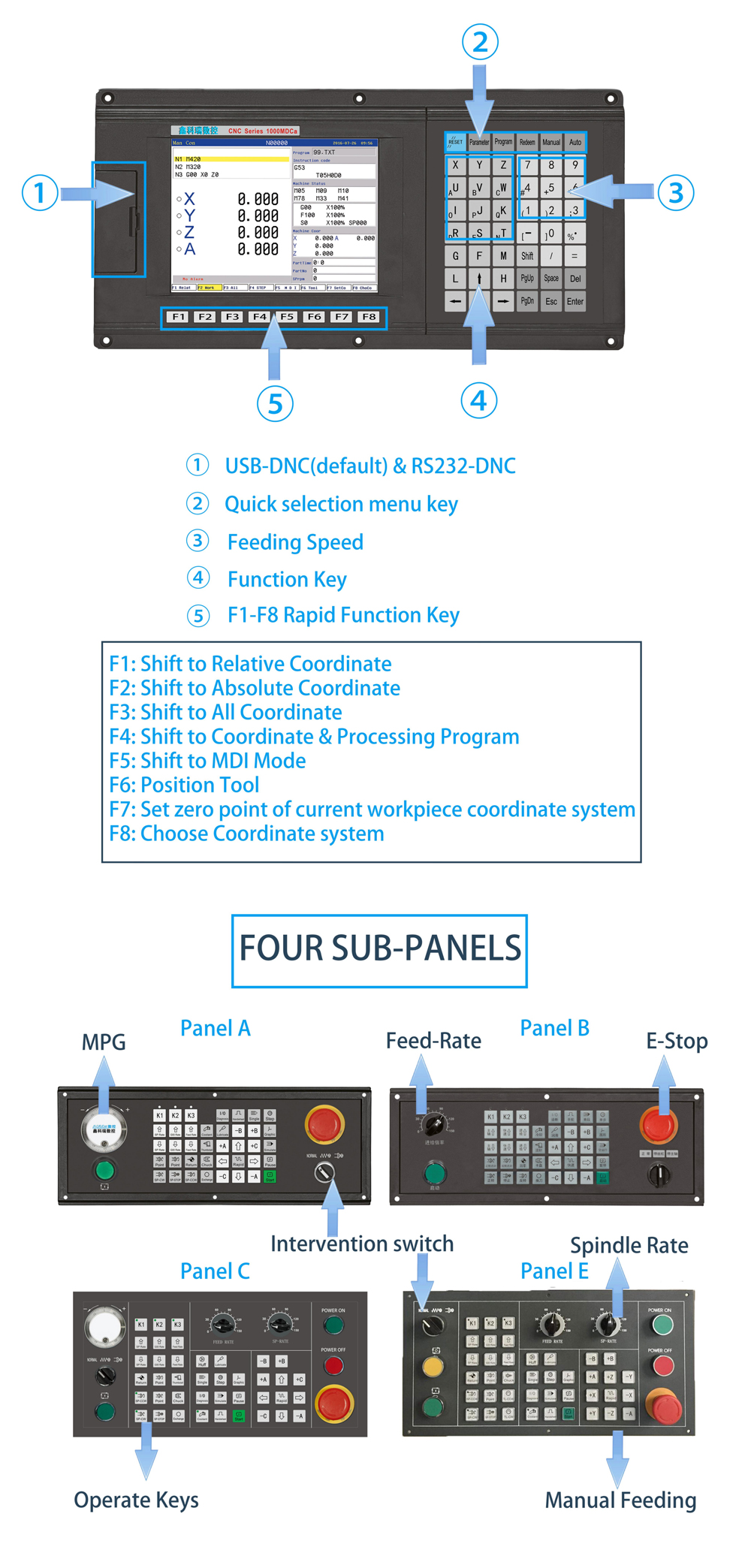

2.Fully Open PLC, macro le alamo lesedi

3.HMI e bonolo (sebopeho sa mochine oa motho), lebokose la lebokose le potlakileng

4.Mekhabiso eohle e bonts'oa 'me e susumelletseha ka Senyesemane

5.Alarm le lintlha tsa phoso ka mantsoe ho fapana le bit parameter

6.Ts'ebetso ea ho hokahanya ha li-axes tsa 5 le holimo, mosebetsi oa RTCP, mosebetsi oa DNC

7.Support Mofuta oa sekhele ATC, mofuta oa letsoho oa mochini oa ATC, mofuta oa mohala oa ATC, mofuta oa Servo oa ATC, mofuta o khethehileng oa ATC

8.Tsupport ho bala turret, encoder turret le servo turret

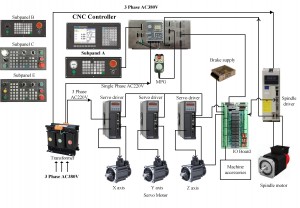

9.Letoto la 1000 le letoto la 1500 le na le mefuta e 4 ea liphanele tse nyane; o ka khetha ho latela litlhoko tsa hau.

10.Molaoli oa CNC oa NEWKer o boetse o tšehetsa tšebeliso ea mechine e fapaneng e khethehileng, e kang mechine ea ho sila, lipolane, mechine e boring, mechine ea ho phunya, mechine ea ho qhekella, mechine ea ho etsa li-gear hobbing, joalo-joalo Mookameli a ka boela a ntlafatsoa ka bobeli. Tšehetsa motho ka mong le moralo.

Lintlha tsa parameter

| Mosebetsi oa tsamaiso | G khoutu e bonts'a | ||

| Palo ea axis ea taolo | 3~8(X,Y,Z,A,B,C,Xs,Ys) | Fumana kapele: | G00 |

| Mananeo a manyane ka ho fetesisa: | 0.001mm | Kenollo ya mola o otlolohileng | G01 |

| Lenaneo le leholo ka ho fetisisa: | ±99999.999mm | Tlhaloso ea Arc: | G02/03 |

| Lebelo le phahameng ka ho fetisisa: | 60m/min | Ho khaola khoele: | G32 |

| Lebelo la phepelo: | 0.001~30m/min | Potoloho ea ho seha cyliner kapa cone: | G90 |

| Bukana e tsoelang pele: | mothapo o le mong kapa mokoloko o mongata ka nako e le nngwe | Phetoho ea ho khaola sefahleho: | G94 |

| Tlhaloso ea mola: | Mohala o otlolohileng, arc, screw thread interpolation | potoloho ea ho poma khoele | G92 |

| Puseletso: | Bolelele ba compensation, radius nko ea puseletso sesebelisoa | Potoloho e tsitsitseng ea ho tlanya | G93 |

| Kenyelletso ea puseletso: | Leka ho seha mokhoa oa ho metha | Potoloho ea ho seha ka mahoashe ka ho pota-pota | G71 |

| Mosebetsi oa spindle: | gear, Taolo ea analoge habeli, Ho tlanya ka thata | Potoloho ea ho seha ka mahlahahlaha qetellong ea sefahleho: | G72 |

| Mosebetsi oa wheelchair: | panel, e tšoaroang ka letsoho | Potoloho ea sehiloeng se koetsoeng | G73 |

| ts'ebetso ea wheelchair: | Mosebetsi oa ho lokisa mabili a letsoho | Potoloho ea lesoba le tebileng sefahlehong | G74 |

| Tšireletso ea skrine: | Ts'ebetso ea ts'ireletso ea skrini | Cycle of cutting groove le bophara ba kantle | G75 |

| Mosebetsi oa ho phomola: | Row tool rest, Motlakase le oona o beha 99 thipa | Potoloho ea ho seha khoele e kopaneng | G76 |

| Mosebetsi oa puisano: | RS232, sebopeho sa USB | Potoloho ea lenaneo | G22,G800 |

| Mosebetsi oa matšeliso: | Puseletso ea lisebelisoa, puseletso ea sebaka, puseletso ea sekhahla, puseletso ea radius | Sistimi ea khokahano ea lehae: | G52 |

| Fetola lenaneo: | Metric / Imperial, Khoele e otlolohileng, khoele ea taper joalo-joalo | Fumana taelo ea ho tlola | G31,G311 |

| Mosebetsi oa boemo ba moeli | moeli o bonolo, moeli o thata | Pole coordinate | G15,G16 |

| mosebetsi oa khoele | metric le inch sebopeho, khoele e otlolohileng, khoele ea taper joalo-joalo | Lenaneo la Metrical/Imperial: | G20,G21 |

| Mosebetsi oa ho bala esale pele: | Bala pele mela e mekhutšoanyane e 10,000 | Beha coordinate, offset | G184,G185 |

| Tšireletso ea password: | Tšireletso ea li-password tse ngata | Sistimi ea khokahano ea mosebetsi: | G54~G59 |

| Kenyelletso/sephetho: | I/O 56*24 | Radius ea lisebelisoa C | G40,G41,G42 |

| Lenaneo la PLC: | Boqapi bohle ba PLC bo bulehileng | Mokhoa o nepahetseng oa ho fumana / o tsoelang pele oa tsela: | G60/G64 |

| Taolo ea ho potlakisa le ho fokotsa lebelo: | Mola o otlolohileng、Index | Kamehla linear cutting: | G96/G97 |

| Nomoro ea khouto: | tlhophiso efe kapa efe | Mokhoa oa ho fepa: | G98,G99 |

| Lenaneo la macro la basebelisi: | Eba le | E tšehetsa ntlha ea ho qala lenaneo: | G26 |

| Mosebetsi oa lisebelisoa tsa motlakase: | Eba le | Ho khutlela sebakeng se tsitsitseng: | G25,G61,G60 |

| Sehlopha se ka tlase | Mofuta o nang le lebili la letsoho; Mofuta oa B o nang le switch ea sehlopha; Mofuta oa C ka bobeli A le B, mofuta oa E | E khutlela sebakeng sa datum: | G28 |

| Kopo: | VMC, ho sila, mochine o khethehileng | Emisa: | G04 |

| Lenaneo la Macro: | G65,G66,G67 | ||

| Mosebetsi o thusang: | S, M, T | ||

Molemo oa mosebetsi

1. parameter e bonolo le e hlakileng, e sa hlokahaleng ho sheba bukana.

2. bula PLC, e ka fetoloa inthaneteng kapa kantle ho marang-rang ho latela litlhoko.

3. Lenaneo la Open Macro, le fumanehang bakeng sa ts'ebeliso e bonolo le nts'etsopele e eketsehileng.

4. Puisano ea bareki, etsa hore ts'ebetso e be bonolo.

5. Bula boema-kepe ba OPC, bo fumanehang bakeng sa ho shebella le ho laola hole.

6.Application: CNC Lathe Machine, CNC Turning Center, Grinding Machine le haholo-holo thepa e itekanetseng

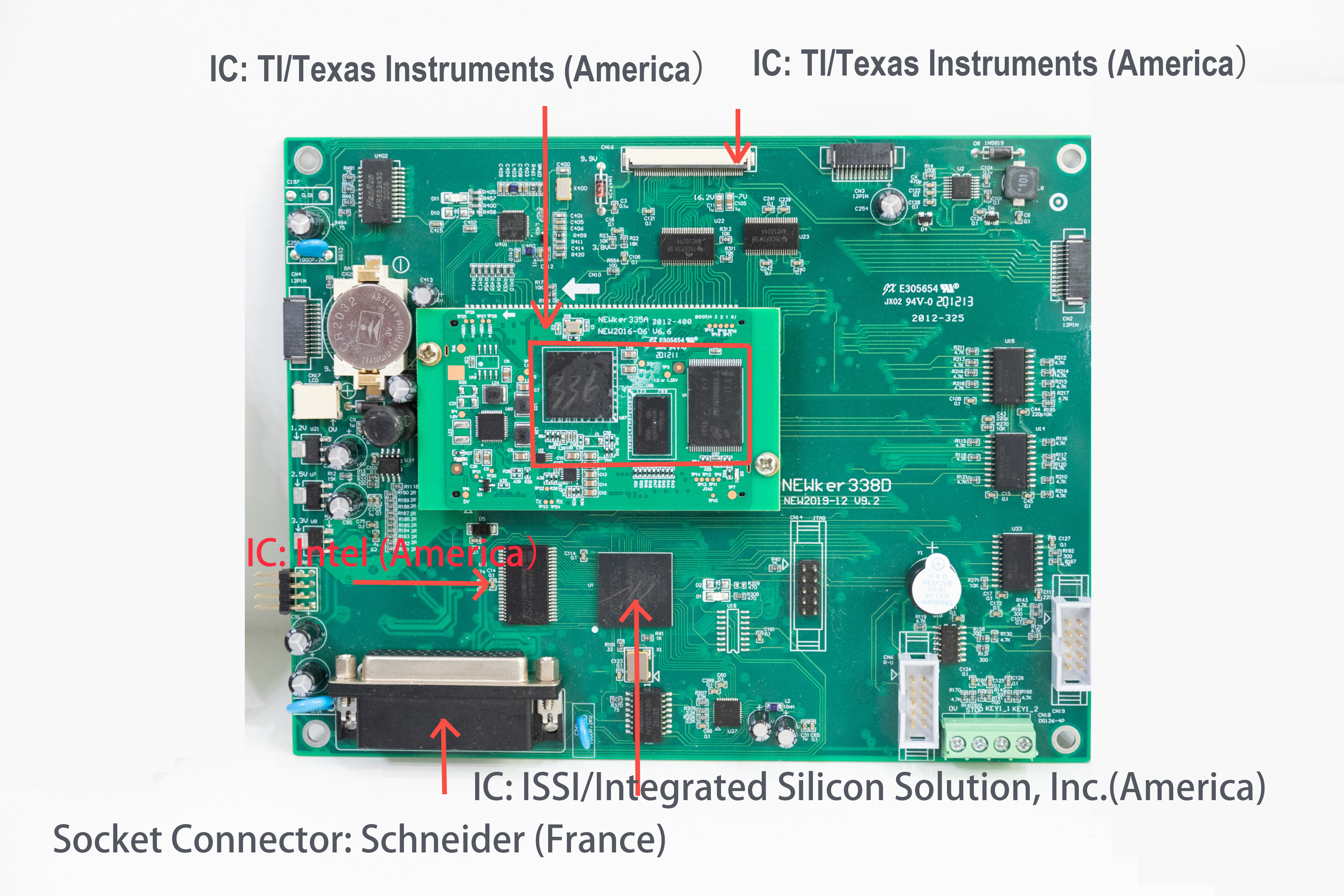

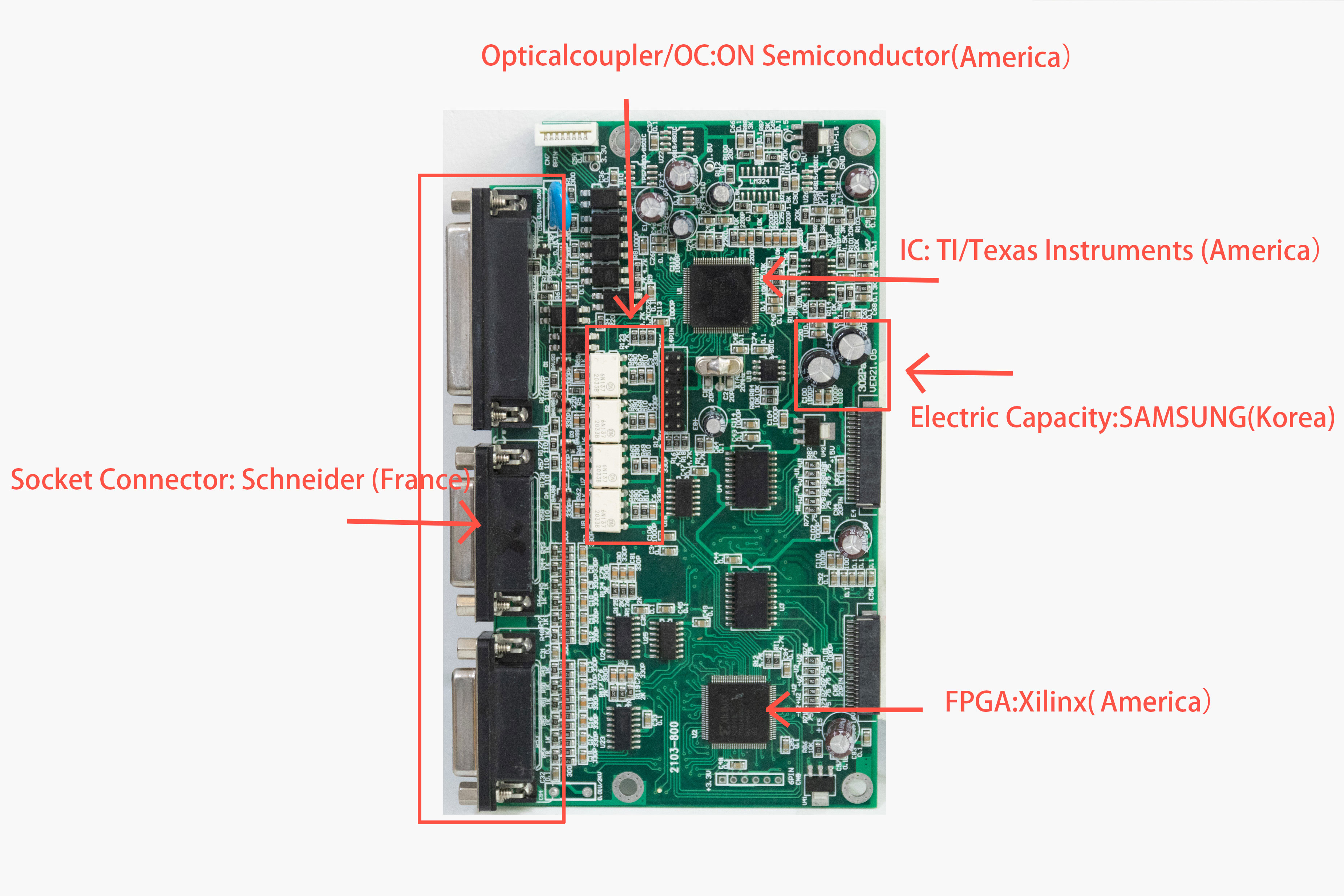

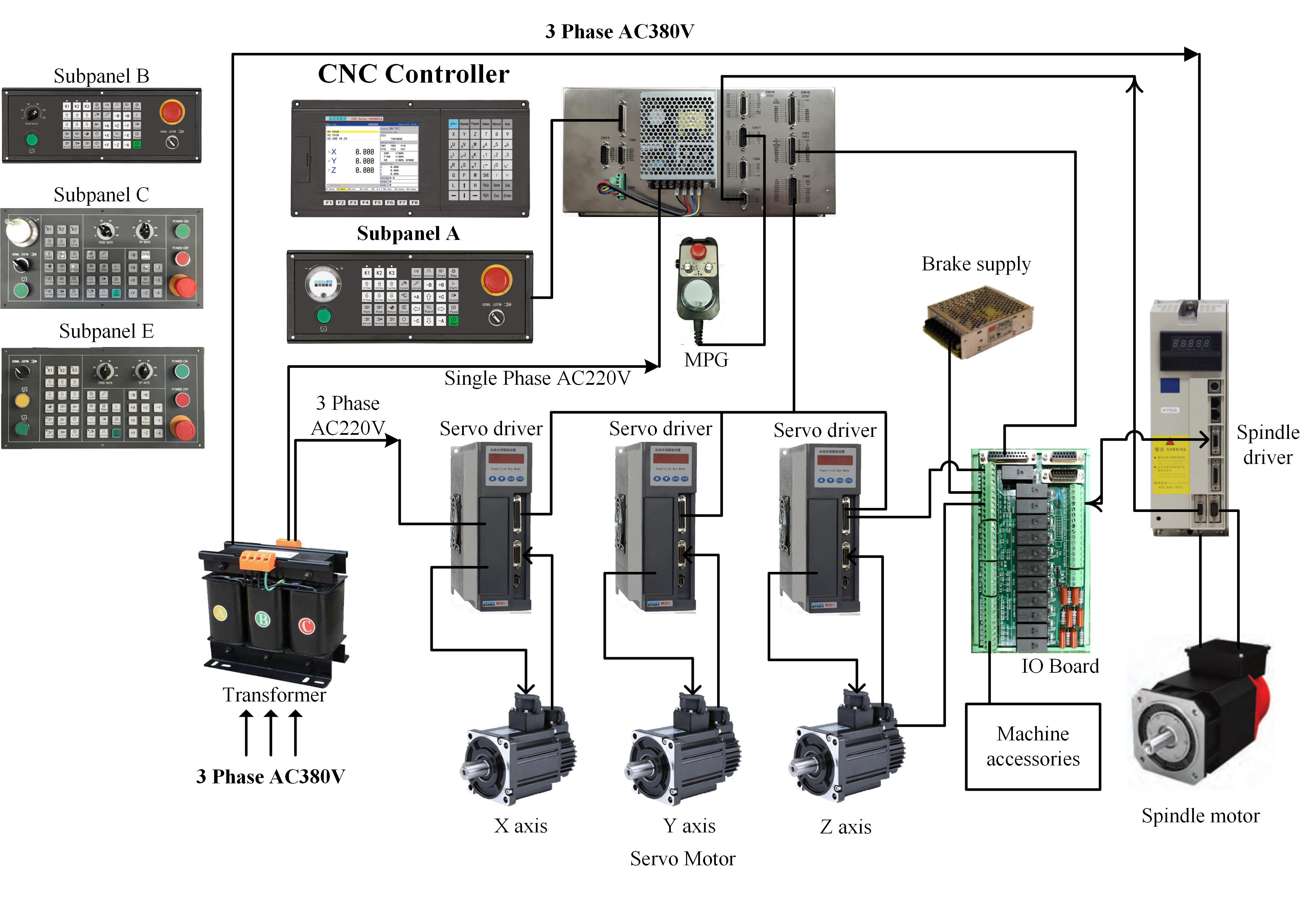

Letšoao la likarolo tsa kahare tseo re li sebelisang ke tse latelang:

1